UGI'RING closes the loop

The aim of UGI'RING is to produce ferro alloys from industrial co-products, and also alkaline and saline batteries, to manufacture Ugitech's stainless steels.

What does this mean for users?

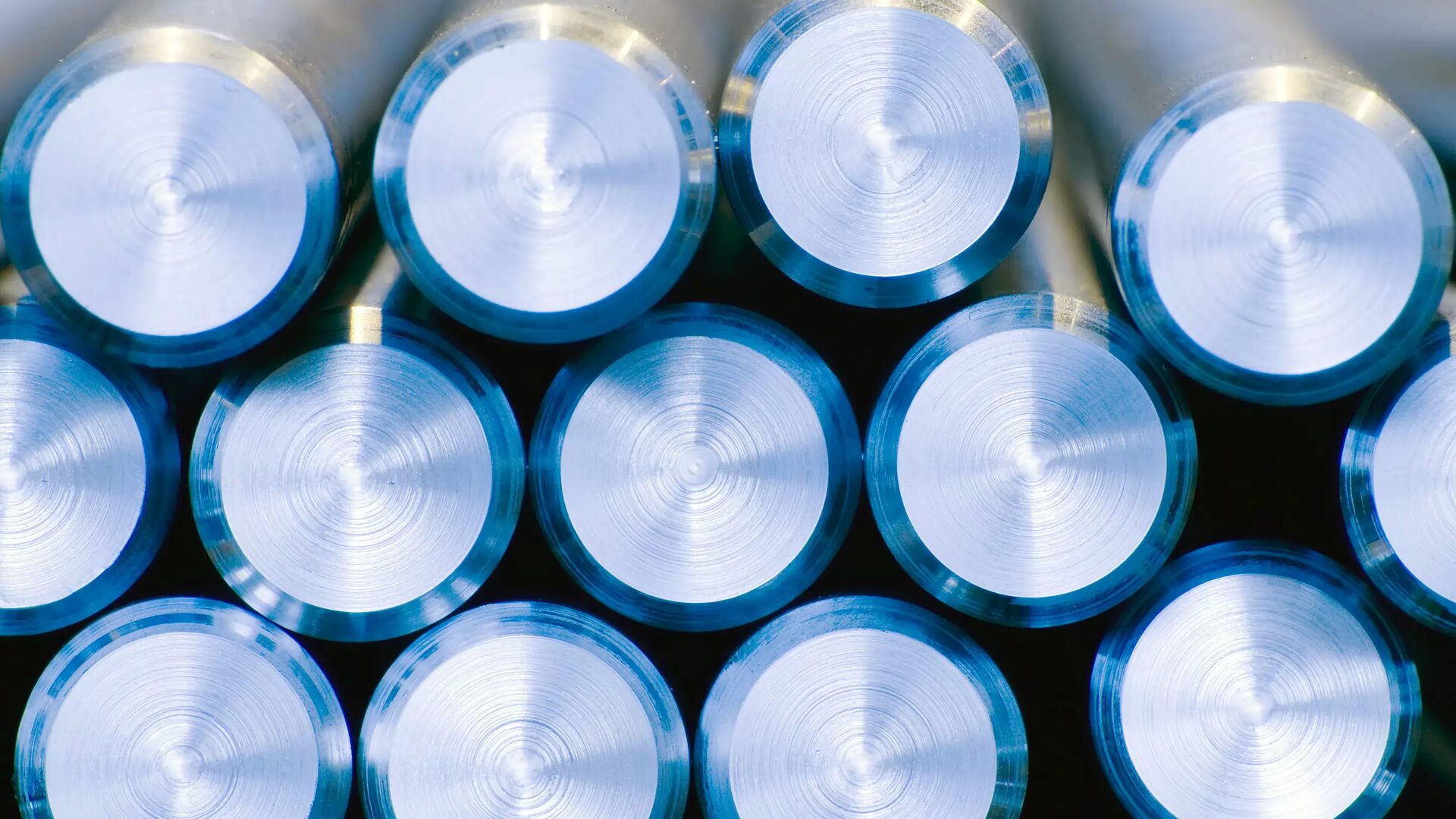

Many products we use every day – from cutlery and surgical instruments to car parts, bridges and leasure products– are made of stainless steel. The quality and durability of these products depend on precisely formulated alloys, in which ferroalloys play a key role.

By recycling used batteries, UGI'RING helps to produce these important alloy components in a resource-efficient manner. These batteries originate from everyday household items such as remote controls, flashlights, wall clocks, toys, and portable radios — devices that often end up in the waste stream after their batteries are depleted. This enables a closed material cycle. The slag, or co-product, from Ugitech, will be recycle which will create the first melting shop in circular economy.

Why is this important?

This circular economy helps to reduce raw material consumption and environmental impact while securing the long-term supply of critical metals. Users benefit from high-quality products whose origin is more sustainable and transparent. Today, these ferroalloys come mainly from Northern Europe, South America and Asia, and are subject to major price fluctuations. UGI'RING aims to position the steel industry as a key player in the recycling of strategic metals, and to contribute to France's sovereignty of supply. It will be one of the most modern industrial recycling facilities in the world.