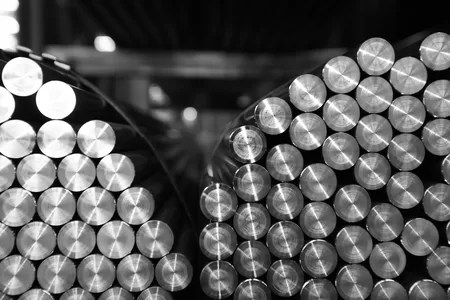

Properties at a glance

Quenched and tempered steels obtain their application properties through austenitizing, quenching and tempering. They cover a minimum tensile strength range of around 470 to 1250 N/mm² in the quenched and tempered condition. In addition to good tensile strength, they are also characterized by high yield strength and ductility. The properties in the final state should be as homogeneous as possible across the cross-section. Compared to quality steels, stainless steels not only have lower phosphorus and sulphur contents but also more uniform properties, for example after heat treatment.