ESP 65

The case-hardening steel for modern cutting machines

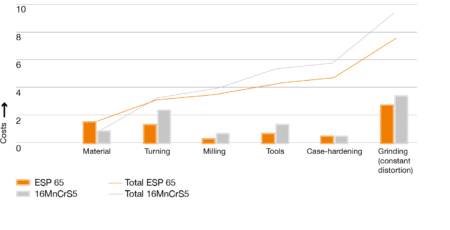

The case-hardening steel ESP 65 was developed specifically for demanding construction materials in modern cutting machines. Compared to 16MnCr5 and 16MnCrS5, ESP 65 offers improved machinability and performance. This excellent machinability leads to shorter machining times, longer tool life and therefore lower process costs. The homogeneous material properties enable precise tolerances and reduce distortion during hardening. Straightening and grinding can be minimized, which further reduces costs.

Specially developed for machining-intensive components

ESP 65 is particularly suitable for machining-intensive components such as gears, worm gears and transmission parts. Thanks to its special properties and manufacturing processes, it has similar machining properties to free-cutting steel, reduces machining stresses and has a positive influence on distortion behavior after hardening. As a result, ESP 65 differs significantly from standard steels.

ESP 65 offers significant cost advantages due to

- high cutting speeds

- higher tool life

- processsafe chip breaking

- ghost trains