Primary and secondary metallurgy

Steel production in our electric arc furnaces

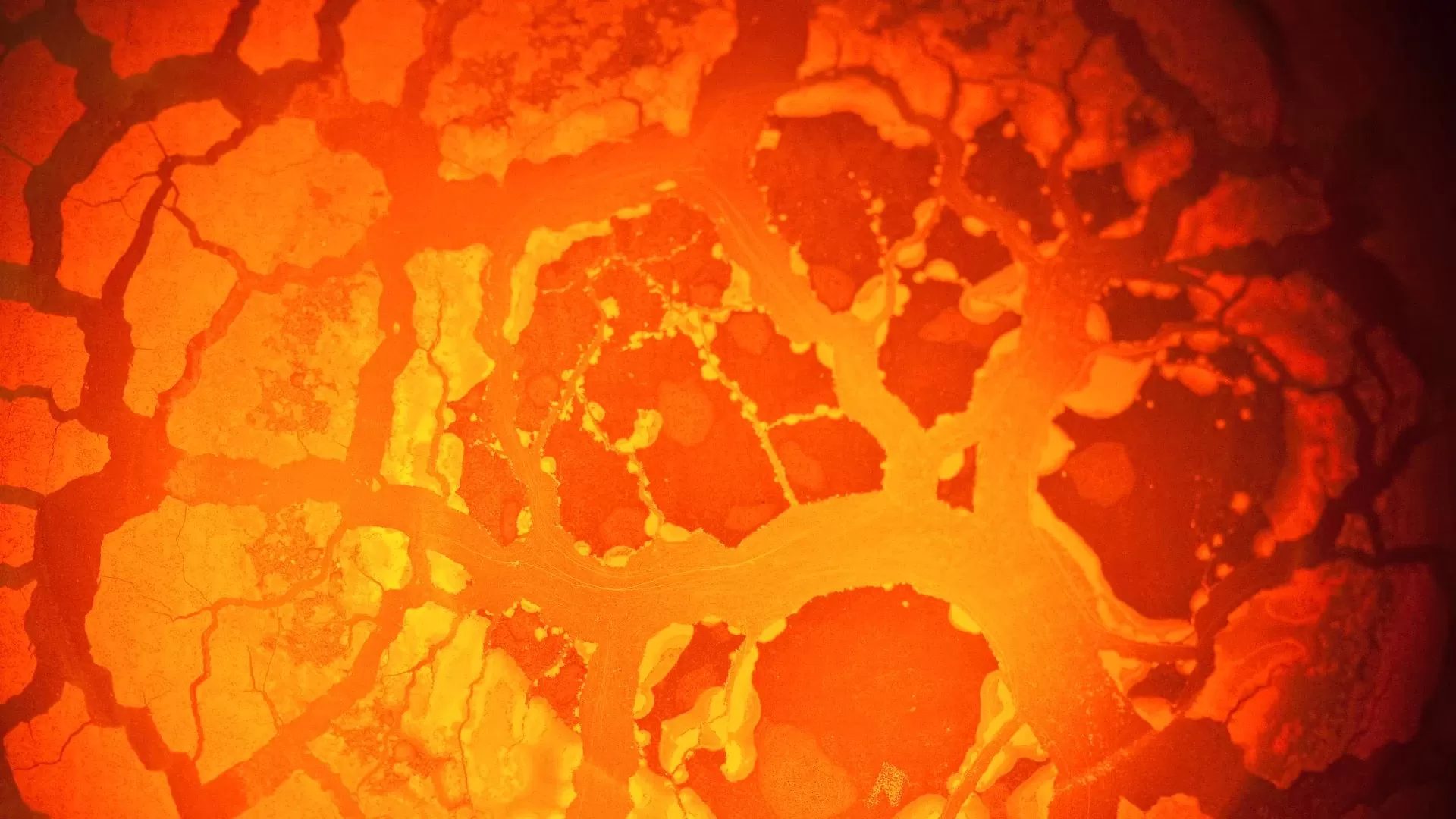

We operate electric arc furnaces at eight locations worldwide, which form the basis of our wide range of products. The main raw material is steel scrap, which is already pre-sorted. At the same time, alloying additives are kept ready to give the melt the desired chemical composition.

The liquid melt is emptied into a ladle. In the ladle, the melt undergoes what is known as secondary metallurgy: Here, degassing takes place, the chemical composition is finalized and excess carbon is removed. Depending on the type of steel, decarbonization takes place under vacuum or in an AOD converter.

The steelworks' job is completed with the casting of the melting batch. A significant proportion of all batches produced are cast in continuous casting. Depending on the type of steel and the desired final dimensions, this is done either in multi-strand circular arc systems (min. 125² - max. 265²) or in vertical casting (475 x 340, 240²). Ingot casting (various formats from min. 1 to max. 27 tons) is used for steels that cannot be cast in a strand, as well as for large forged products. Electrodes are also provided for remelting operations.

Although the content of contaminating secondary elements, such as phosphorus and sulphur, is already below standard specifications in the steelworks, the use of tertiary metallurgy is necessary for special requirements, which is operated at Swiss Steel Group with several plants.