Use of high-speed steels

High-speed steel is characterized by its high hardness, wear resistance, heat resistance, and good toughness. These properties make it particularly suitable for tools operating under extreme conditions, such as drills, end mills, taps, and reamers. High-speed steel allows these tools to cut precisely and efficiently at high speeds while maintaining their sharpness over extended periods.

The outstanding properties of high-speed steel result from its specific chemical composition. It contains a combination of alloying elements such as tungsten, molybdenum, vanadium, and cobalt, which enhance its hardness, wear resistance, and heat resistance. These alloying elements also contribute to the formation of carbides, which are responsible for the steel's hardness.

To achieve the final properties, high-speed steel undergoes a specialized heat treatment process known as hardening and tempering. This process imparts hardness and wear resistance to the steel while simultaneously increasing its toughness.

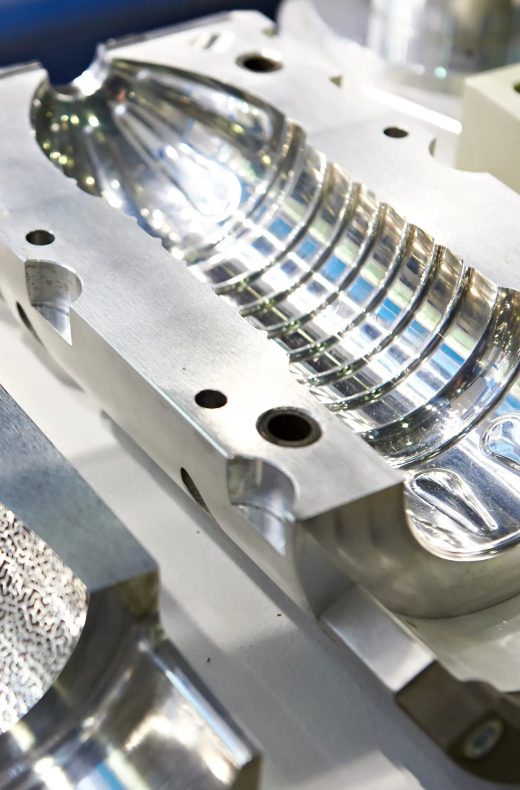

Another advantage of high-speed steel is its versatility. It can be used for a variety of applications, both in machining metals and processing non-metallic materials such as plastics and wood.

Due to its high hardness, high-speed steel is more challenging to machine and requires special tools and machinery.

Overall, high-speed steel is an indispensable material in the tool industry, employed in various applications due to its high hardness, wear resistance, heat resistance, and toughness. With its ability to cut precisely at high speeds and maintain sharpness for extended periods, high-speed steel is a crucial component of many high-performance tools.