Top12

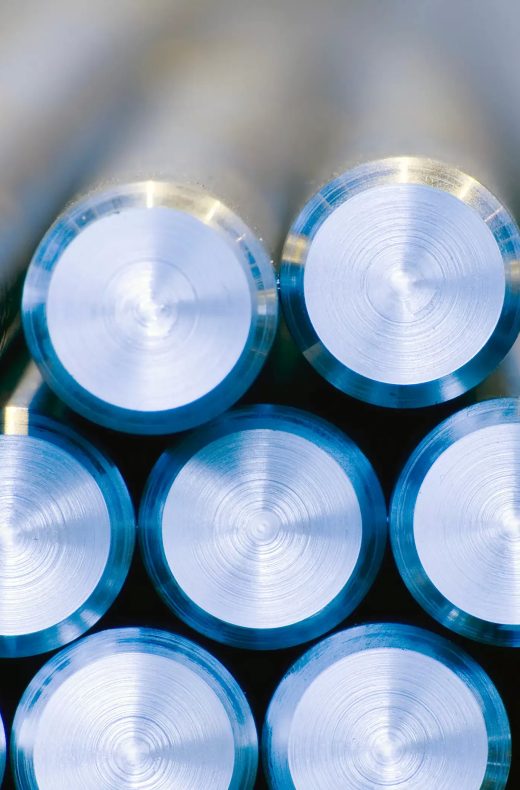

Top12 is an innovative reinforcing steel with a superior corrosion resistance and the lowest life cycle costs in its class. Top12:

- is a high-alloy material of grade 1.4003 with higher corrosion-resistance than conventional reinforcing steel, as it contains at least 12 percent chromium by mass.

- requires no special handling and can be processed conventionally.

- is approx. four times more resistant to chlorides than conventional reinforcing steel. This reliable protection against corrosion can extend the service life of buildings many times over.

- requires very little concrete cover due to its higher corrosion resistance in the event of chloride or CO2 impact.

- in its geotechnical version with higher yield strength, makes the usual anchor system sleeve superfluous, as it offers the necessary protection for temporary and permanent anchoring of protection level 2 in any subsoil - even in aggressive groundwater.