Industrial knives: Innovative material solutions

Industrial knives are used in various industries to cut, separate or shape materials. The optimum material and the right tool depend on the type of material, be it paper, metal, wood or plastic. In the recycling industry, the Swiss Steel Group offers special high-nickel alloyed cold work steels in forged design for shredding in scrap shredding machines. Cryodur 2379, Cryodur 2990, Cryodur 2360, Cryodur 2746 (e.g. for scrap shear blades) and Cryodur 2363 from the cold-work tool steel range are suitable for meeting the increasing demands on mechanical properties and toughness. These materials meet the demanding requirements of the recycling sector.

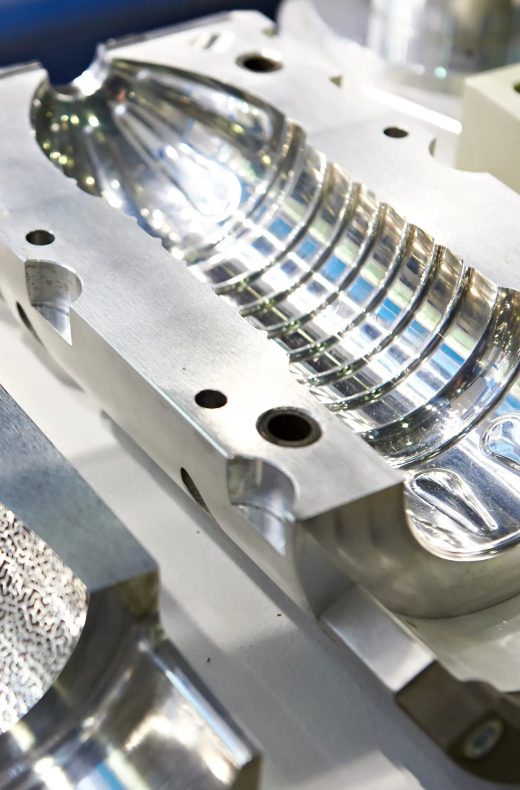

The shredding of metallic, mineral, plastic and wood materials is an important economic factor in industrial production processes. The demands placed on tools in terms of wear, impact resistance and hardness are extreme. Highly wear-resistant ledeburitic chromium steel is used for granulating plastics, while Ferro-Titanit® ensures extreme wear resistance for the highest requirements.

Alloyed cold-work tool steel has been developed for chipping tools and in particular for wood processing. This is characterized by a sufficiently high hardness combined with high toughness and high wear resistance.